© 2014 Ashtron Global Pte Ltd. All Rights Reserved.

Made by Serif

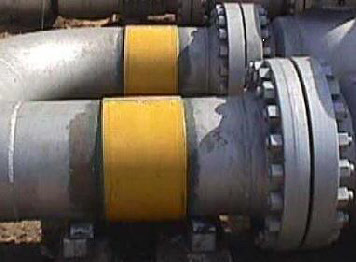

Pipe Support Corrosion Prevention System

Clock Spring’s Pipe Support corrosion prevention system is perfect for terminals, plants, refineries, new pipeline construction, and any pipe support location. The system architecture changes with the diameter of the pipe.

For pipe diameters 6″ or less there are two options. Our clients can select two layers

of continuous composite material or two split sleeves. Both of these options have

materials oriented bi-

For Pipe Support locations 8”or more there are two options. The first option contains two continuous layers of unidirectional material and an additional third split sleeve layer with bidirectional material. The second option for 8”+ contains two split sleeves containing unidirectional material and a top layer split sleeve containing bidirectional material.

All of our pipe support systems create a sacrificial wear plate eliminating crevice corrosion. The outside layer can handle the weight of the pipe and any abrasion from pipe movement. The resin acts as a bearing surface and the glass is a tough component that protects the inner layers. The inner layers provide redundant 360 degree protection around the pipe. These products have been in active service for over a decade in various environments and in many specialized applications.

The fiberglass composite sleeve is uniquely coil-